Sanitising Conveyors

Sanitising Conveyors

The BRC Global Standard for Food Safety requires there to be physical segregation between low and high care areas.

SYSPAL Sanitising Conveyors are the ideal product to meet this requirement. Allowing the operator to pass utensils, raw ingredients still in their packaging and equipment through the segregation barrier between low and high care areas.

The benefits provided by SYSPAL sanitising conveyors

- Convey ingredients, utensils and equipment from low to high care areas with confidence that they’re fully sanitised.

- Robust design with good access for routine hygiene cleaning and maintenance procedures

- Products such as bagged food, cans, tubs, blocks of cheese, film reels, etc are sanitised before entering a high care food environment for further processing

- Certain optional feature components can be added at a later stage to suit standard panel functions

- Infeed sensor starts spray bar and conveyor when product passes and comes with a variable timer and switch off function to provide energy saving facility

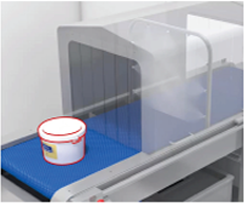

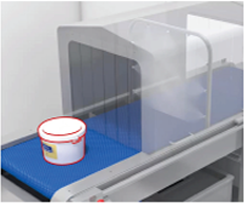

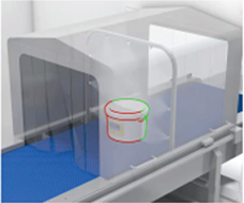

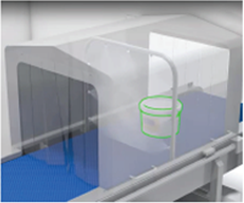

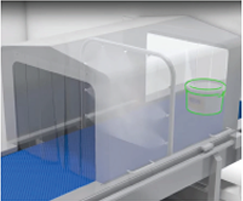

The Production Flow

Product is bought in on pallets

Sanitiser is used to take items from low care to high care

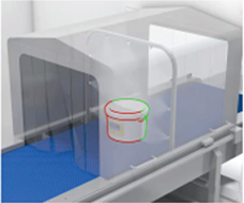

Product goes from low care (red) to high care (green)

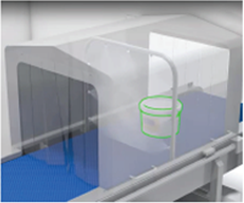

Solution from the stainless steel jet nozzles is sprayed over the product sanitising it

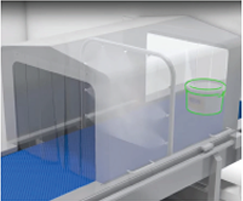

Once passed under the nozzles the product is sanitised

Product is safe for a high care environment

Types of Sanitising Conveyors

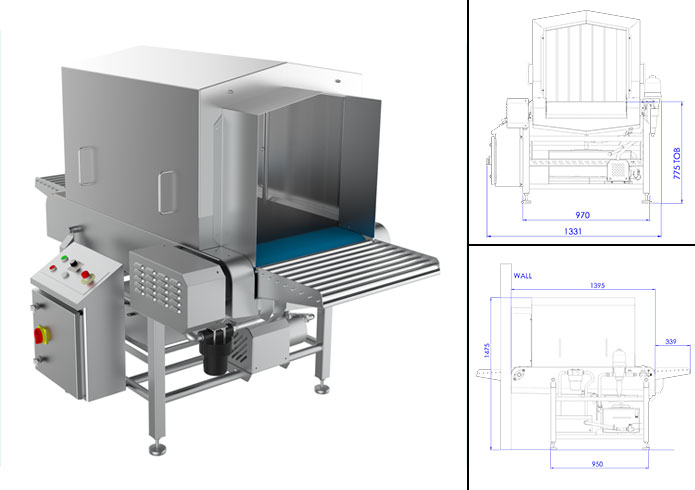

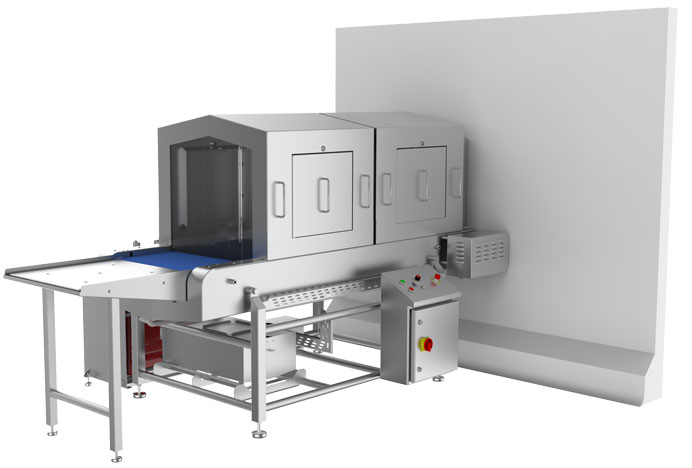

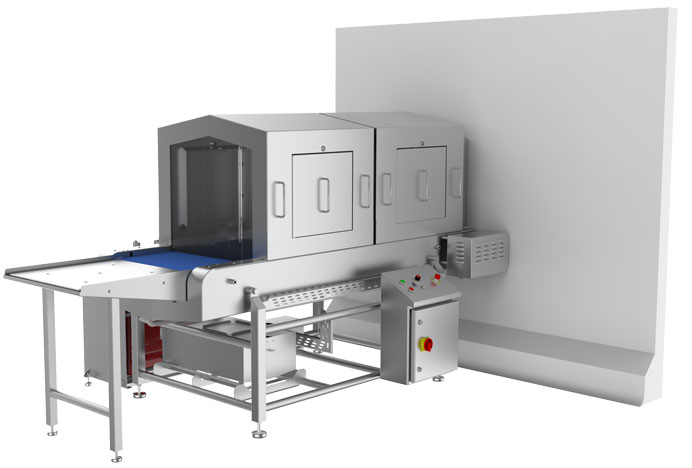

Standard Short Sanitiser

Short model sanitising conveyor interfaces with segregating wall for taking products through from low care to high care to meet the requirements of the BRC Global Standards for Food Safety.

Products such as bagged food, cans, tubs, blocks of cheese, films reels are sanitised before entering a high care food environment for further processing.

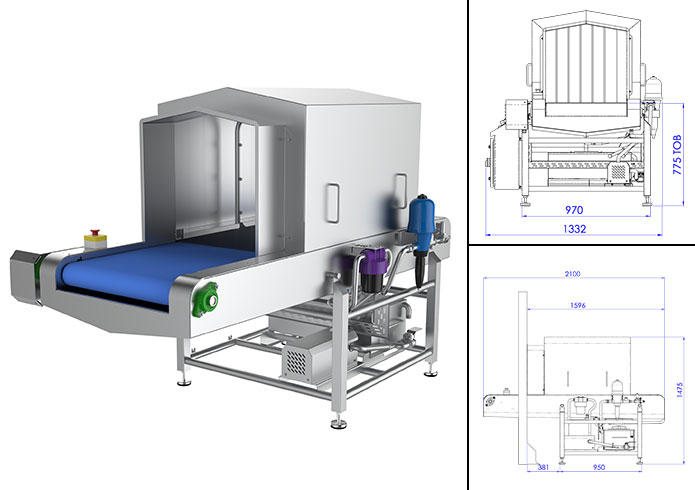

Standard Long Sanitiser

Long model sanitising conveyor with auto fill and full recirculation system. Manually loaded conveyor with remote Etop facility.

Longer conveyor belt extends through a segregating wall transfer hatch into a high care environment.

Specification features for standard sanitisers

- 304 stainless steel

- 50 Micron filter as standard

- Lift off stainless steel hood for easy cleaning

- 596mm wide polymer open grid for conveyor

- 360° loop spray nozzle set to ensure maximum product coverage

- Dosatron chemical dosing unit with adjustable rate of 0.2% - 2.0%

- All legs complete with adjustable feet

- Infeed product sensor for operation start

- Variable timed delay function on outfeed sensor

- Variable conveyor drive nominal speed - 10mtrs/min @ 50Hz

- Side mounted, IP67 rated control panel

- Removable sanitising solution tank with recirculation mesh filter, drain valve and overflow facility

Options for bespoke sanitising requirements

Bespoke Twin Spray Bar Sanitising Conveyor with Double Chamber

Amendments to the standard specification can be quoted to suit the final specification

Options available:

- Infeed and Outfeed gravity roller tracks with easy removable rollers and track units

- Infeed and Outfeed tables with perforated drain facility back to tank & easy removable deck and table unit

- Side guides through tunnel hood

- Sanitising solution can be fed direct from customers sanitiser main tank to solenoid valve

- Used solution can go direct to drain or pumped to drain from the holding tank

- Infeed and Outfeed product sensors

- 200 Micron filter system in addition to standard 50 Micron filter

- Straight through belt for small products and difficult to handle products

- Twin belt arrangement to suit high care to low care segregation requirements

- Reversing belt type (straight through belt only) to allow product to be returned from high care following end of production process i.e tray return or unused product

- Mobile with stainless steel lockable braked swivel castors

- Panel controls can be internally mounted to prevent unauthorised adjustment

- Air knife facility to remove surplus solution

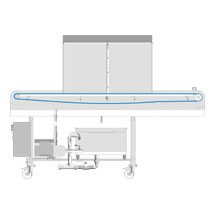

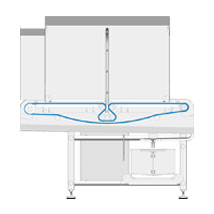

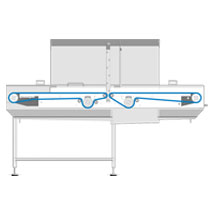

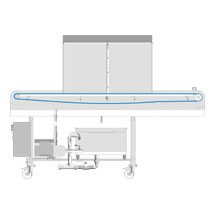

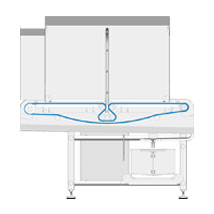

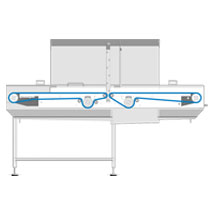

Different high care environments require different belt configurations - we offer three different types of belt configurations for you to select from.

Straight through belt

Looped belt

High care / low care

separated belt

Please call our expert conveyors team on (0)1952 883188 for advice and support. We can help you build your ideal sanitising solution for low care to high care product transfers.

Sanitising Conveyors

The BRC Global Standard for Food Safety requires there to be physical segregation between low and high care areas.

SYSPAL Sanitising Conveyors are the ideal product to meet this requirement. Allowing the operator to pass utensils, raw ingredients still in their packaging and equipment through the segregation barrier between low and high care areas.

The benefits provided by SYSPAL sanitising conveyors

- Convey ingredients, utensils and equipment from low to high care areas with confidence that they’re fully sanitised.

- Robust design with good access for routine hygiene cleaning and maintenance procedures

- Products such as bagged food, cans, tubs, blocks of cheese, film reels, etc are sanitised before entering a high care food environment for further processing

- Certain optional feature components can be added at a later stage to suit standard panel functions

- Infeed sensor starts spray bar and conveyor when product passes and comes with a variable timer and switch off function to provide energy saving facility

The Production Flow

Product is bought in on pallets

Sanitiser is used to take items from low care to high care

Product goes from low care (red) to high care (green)

Solution from the stainless steel jet nozzles is sprayed over the product sanitising it

Once passed under the nozzles the product is sanitised

Product is safe for a high care environment

Types of Sanitising Conveyors

Standard Short Sanitiser

Short model sanitising conveyor interfaces with segregating wall for taking products through from low care to high care to meet the requirements of the BRC Global Standards for Food Safety.

Products such as bagged food, cans, tubs, blocks of cheese, films reels are sanitised before entering a high care food environment for further processing.

Standard Long Sanitiser

Long model sanitising conveyor with auto fill and full recirculation system. Manually loaded conveyor with remote Etop facility.

Longer conveyor belt extends through a segregating wall transfer hatch into a high care environment.

Specification features for standard sanitisers

- 304 stainless steel

- 50 Micron filter as standard

- Lift off stainless steel hood for easy cleaning

- 596mm wide polymer open grid for conveyor

- 360° loop spray nozzle set to ensure maximum product coverage

- Dosatron chemical dosing unit with adjustable rate of 0.2% - 2.0%

- All legs complete with adjustable feet

- Infeed product sensor for operation start

- Variable timed delay function on outfeed sensor

- Variable conveyor drive nominal speed - 10mtrs/min @ 50Hz

- Side mounted, IP67 rated control panel

- Removable sanitising solution tank with recirculation mesh filter, drain valve and overflow facility

Options for bespoke sanitising requirements

Bespoke Twin Spray Bar Sanitising Conveyor with Double Chamber

Amendments to the standard specification can be quoted to suit the final specification

Options available:

- Infeed and Outfeed gravity roller tracks with easy removable rollers and track units

- Infeed and Outfeed tables with perforated drain facility back to tank & easy removable deck and table unit

- Side guides through tunnel hood

- Sanitising solution can be fed direct from customers sanitiser main tank to solenoid valve

- Used solution can go direct to drain or pumped to drain from the holding tank

- Infeed and Outfeed product sensors

- 200 Micron filter system in addition to standard 50 Micron filter

- Straight through belt for small products and difficult to handle products

- Twin belt arrangement to suit high care to low care segregation requirements

- Reversing belt type (straight through belt only) to allow product to be returned from high care following end of production process i.e tray return or unused product

- Mobile with stainless steel lockable braked swivel castors

- Panel controls can be internally mounted to prevent unauthorised adjustment

- Air knife facility to remove surplus solution

Different high care environments require different belt configurations - we offer three different types of belt configurations for you to select from.

Straight through belt

Looped belt

High care / low care

separated belt

Please call our expert conveyors team on (0)1952 883188 for advice and support. We can help you build your ideal sanitising solution for low care to high care product transfers.