Double Column Tipper

Double Column Tipper

Lift & Tip SYSPAL HEAVY DUTY

The SYSPAL Double Column Tipper can handle up to 1500kg of product feeding high level hoppers, vibratory conveyors and other process equipment. Ideal for bulk feed handling and reducing the risk of musculoskeletal injuries associated with emptying dolavs, tanks, bowls etc.

A flexible design with bespoke tip heights, tip angles and production line integration options to meet individual requirements.

- Lifts and tips product into a vessel or hopper

- Designed for containers such as dolavs, tanks and bowls

- Safe working load of 1500kg

- Lifting speeds of 6m/min

- Automatic operation

- Sensor confirms correct position of container

- Fixed sheet panel guards

- Doors interlocked with magnetic safety switches

- IP65 minimum rating

- 45° Tipping angle

Double Column Tipper Applications

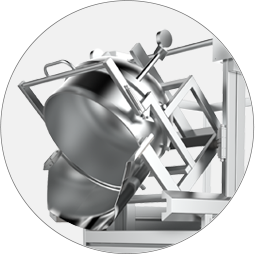

Mixing Bowls

- Single Column Tipper has a bin rotation up to 55° tipping angle. Ideal for dough/pastry products, viscose liquid and free flowing grains and powders

- High load capacity of 350kg

- Mobile or bolt down base options

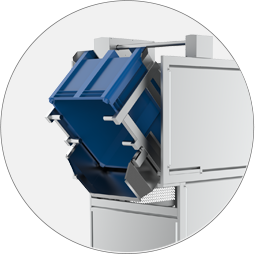

Dolav Double Column Tipper

- Single Column Tipper has a bin rotation up to 55° tipping angle. Ideal for dough/pastry products, viscose liquid and free flowing grains and powders

- High load capacity of 350kg

- Mobile or bolt down base options

Tank Double Column Tipper

- Tank Double Column Tipper has a bin rotation up to 45° tipping angle. Designed to tip a variety of containers and dolavs with weights and heights to suit most applications

- High load capacity of 150kg

- Can be supplied with guarding and interlocking gates for safety

Double Column Tipper

Lift & Tip SYSPAL HEAVY DUTY

The SYSPAL Double Column Tipper can handle up to 1500kg of product feeding high level hoppers, vibratory conveyors and other process equipment. Ideal for bulk feed handling and reducing the risk of musculoskeletal injuries associated with emptying dolavs, tanks, bowls etc.

A flexible design with bespoke tip heights, tip angles and production line integration options to meet individual requirements.

- Lifts and tips product into a vessel or hopper

- Designed for containers such as dolavs, tanks and bowls

- Safe working load of 1500kg

- Lifting speeds of 6m/min

- Automatic operation

- Sensor confirms correct position of container

- Fixed sheet panel guards

- Doors interlocked with magnetic safety switches

- IP65 minimum rating

- 45° Tipping angle

Double Column Tipper Applications

Mixing Bowls

- Single Column Tipper has a bin rotation up to 55° tipping angle. Ideal for dough/pastry products, viscose liquid and free flowing grains and powders

- High load capacity of 350kg

- Mobile or bolt down base options

Dolav Double Column Tipper

- Single Column Tipper has a bin rotation up to 55° tipping angle. Ideal for dough/pastry products, viscose liquid and free flowing grains and powders

- High load capacity of 350kg

- Mobile or bolt down base options

Tank Double Column Tipper

- Tank Double Column Tipper has a bin rotation up to 45° tipping angle. Designed to tip a variety of containers and dolavs with weights and heights to suit most applications

- High load capacity of 150kg

- Can be supplied with guarding and interlocking gates for safety