Single Column Tipper

Single Column Tipper

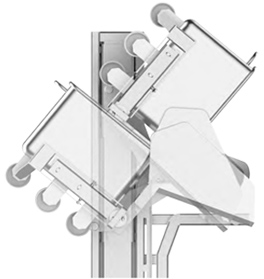

Versatile Single Column Tippers

SYSPAL have designed a versatile column tipper range to take the strain out of manual handling, reducing the risk of injury, whilst increasing efficiency. All tippers have a simple to use, single operator process.

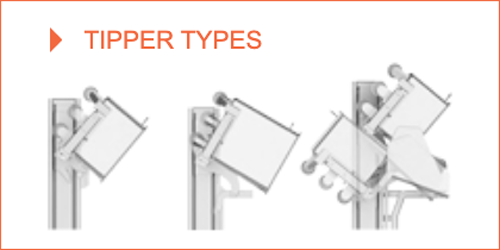

Tippers are designed for 200 and 300 litre Eurobins, tote bins, bakery mixing bowls, tanks, wheelie bins, dolavs and containers. The tippers can be specified left or right tip, mobile or static, guarded or skeletal, with or without bump rail.

Each unit has a lifting speed of 6 metres per minute and operate in environments from -10 °C to 40° C. Manufactured from 304 grade stainless steel, which is exceptionally easy to sanitise and is perfect for the food and pharmaceutical industries.

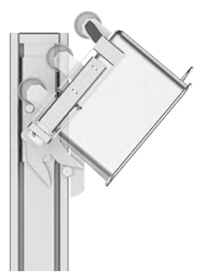

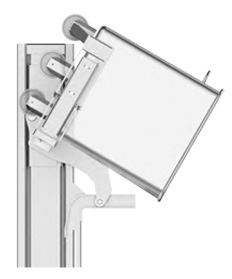

SYSPAL design column tippers with an emphasis on hygiene and safety. Column tippers are specified with chainbreak mechanisms, various guarding options, high and low level lift carriage limit switches, lift column chain guards, external control panels, guarding and interlocking gates. The tippers have sensors which confirm the correct position of the item to be lifted.

Single Column Tipper Applications

Eurobins

- Accommodates a full range of Eurobins

- Bespoke tranfer chutes available to suit specific applications

- Mechanical bin retention prevents lift operation in event of incorrect Eurobin loading

Mixing Bowls

- Single Column Tipper has a bin rotation up to 55° tipping angle. Ideal for dough/pastry products, viscose liquid and free flowing grains and powders

- High load capacity of 350kg

- Mobile or bolt down base options

Wheelie Bins

- Safe transfer of waste, designed to reduce handling and be easy to clean

- Wheelie bins are tipped to a 55° angle to ensure all waste is removed

- Mobile units for easy repositioning with a 250kg lift load

Barrel Drums

- Single Column Tippers can be manufactured to lift and tip a variety of barrels and drums

- All tippers have an Anti-fall chain break mechanism preventing the lift from falling in the event of chain failure

Trays

- Specifically designed for the lifting and transferring of trays

- Designed for 600 x 400 eurotrays and all tray sizes uses within the food and pharmaceutical industries

- Available with various guarding options

Custom Containers

- Single Column Tipper carriages can be manufactured to specifically suit your container and the product you are transferring

- Left or right tip, mobile or static, guarded or skeletal, with or without bump rail

Single Column Tipper

Versatile Single Column Tippers

SYSPAL have designed a versatile column tipper range to take the strain out of manual handling, reducing the risk of injury, whilst increasing efficiency. All tippers have a simple to use, single operator process.

Tippers are designed for 200 and 300 litre Eurobins, tote bins, bakery mixing bowls, tanks, wheelie bins, dolavs and containers. The tippers can be specified left or right tip, mobile or static, guarded or skeletal, with or without bump rail.

Each unit has a lifting speed of 6 metres per minute and operate in environments from -10 °C to 40° C. Manufactured from 304 grade stainless steel, which is exceptionally easy to sanitise and is perfect for the food and pharmaceutical industries.

SYSPAL design column tippers with an emphasis on hygiene and safety. Column tippers are specified with chainbreak mechanisms, various guarding options, high and low level lift carriage limit switches, lift column chain guards, external control panels, guarding and interlocking gates. The tippers have sensors which confirm the correct position of the item to be lifted.

Single Column Tipper Applications

Eurobins

- Accommodates a full range of Eurobins

- Bespoke tranfer chutes available to suit specific applications

- Mechanical bin retention prevents lift operation in event of incorrect Eurobin loading

Mixing Bowls

- Single Column Tipper has a bin rotation up to 55° tipping angle. Ideal for dough/pastry products, viscose liquid and free flowing grains and powders

- High load capacity of 350kg

- Mobile or bolt down base options

Wheelie Bins

- Safe transfer of waste, designed to reduce handling and be easy to clean

- Wheelie bins are tipped to a 55° angle to ensure all waste is removed

- Mobile units for easy repositioning with a 250kg lift load

Barrel Drums

- Single Column Tippers can be manufactured to lift and tip a variety of barrels and drums

- All tippers have an Anti-fall chain break mechanism preventing the lift from falling in the event of chain failure

Trays

- Specifically designed for the lifting and transferring of trays

- Designed for 600 x 400 eurotrays and all tray sizes uses within the food and pharmaceutical industries

- Available with various guarding options

Custom Containers

- Single Column Tipper carriages can be manufactured to specifically suit your container and the product you are transferring

- Left or right tip, mobile or static, guarded or skeletal, with or without bump rail