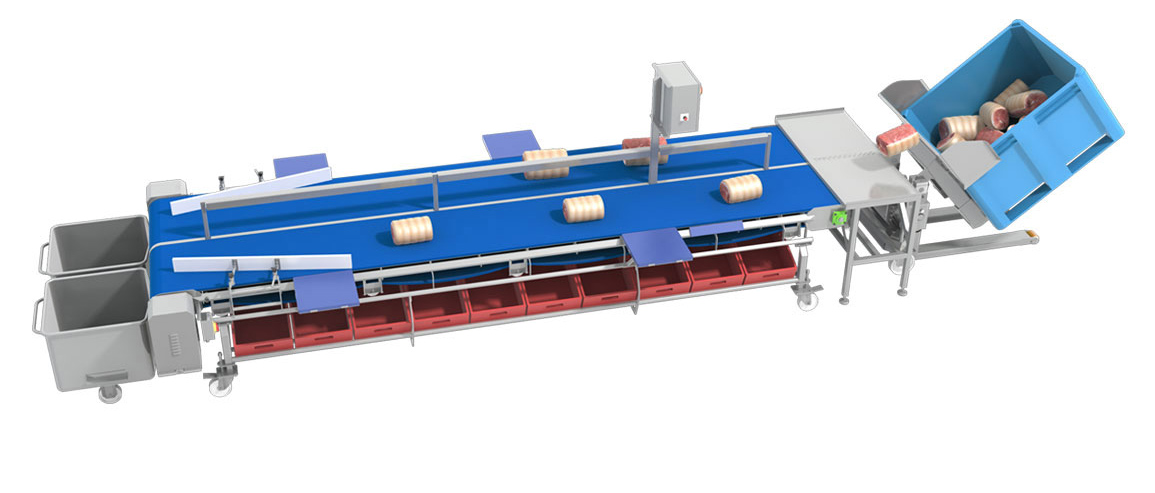

Bespoke Boning Line Conveyor

Where Efficiency "Meats" Design

Dolav handling combined with a twin lane belt conveyor for meat processing

applications such as boning and cutting in bulk

Used in this project:

Learn More About This Project:

We were asked by a leading meat processor to develop a way to improve efficiency and throughput of meat processing applications such as boning and cutting. Several important elements to consider were improving productivity whilst maintaining employee safety and meeting the strict hygiene standards required.

Our experienced design team put together a bespoke solution for transporting and unloading the meat product in bulk using our dolav handling equipment. Our robust Dolav Tilter eliminates the need for manual lifting which significantly reduces the risks of staff developing costly musculoskeletal injuries. With its tipping height of 920mm and its tipping angle of 85° depositing the product is a simple and efficient process.

The next element of the project was to develop a conveyor system that could significantly improve throughput whilst still allowing for efficient manual grading of product. The ideal salutation was a Twin lane belt conveyor which allowed twice the product to be processed at once, doubling productivity. However each belt has a variable speed setting to allow operators to set the belt to process product at a speed that is comfortable and safe for them.

Sliding cutting boards with blade protecting covers allow for the operator to easily take product from the conveyor to cut depending on application. The incorporation of tray storage underneath also allows for the easy removal of off cuts or rejects to maintain quality. To ensure the system meets the tough demands of meat processing applications the belts are impact resistant and designed to be accessible for intensive manual cleaning. Adjustable product guides at the end of the conveyor mean that product can be directed into a Eurobin ready to move on to the next stage of the manufacturing process.

This conveyor system compatible with dolav handling equipment and Eurobins was designed to specific dimension provided to us. However thanks to our manufacturing and design capabilities we are able to develop and manufacture solutions to different sizes and specifications depending on application and requirements.

SYSPAL's meat processing line was well received by the customer and fit in well with their existing production processes whilst helping to create a more efficient and lean meat processing line. If you have a similar meat processing requirement, or simply need to improve production efficiency and throughput why not contact us and see what we can do for you?

View The Animation

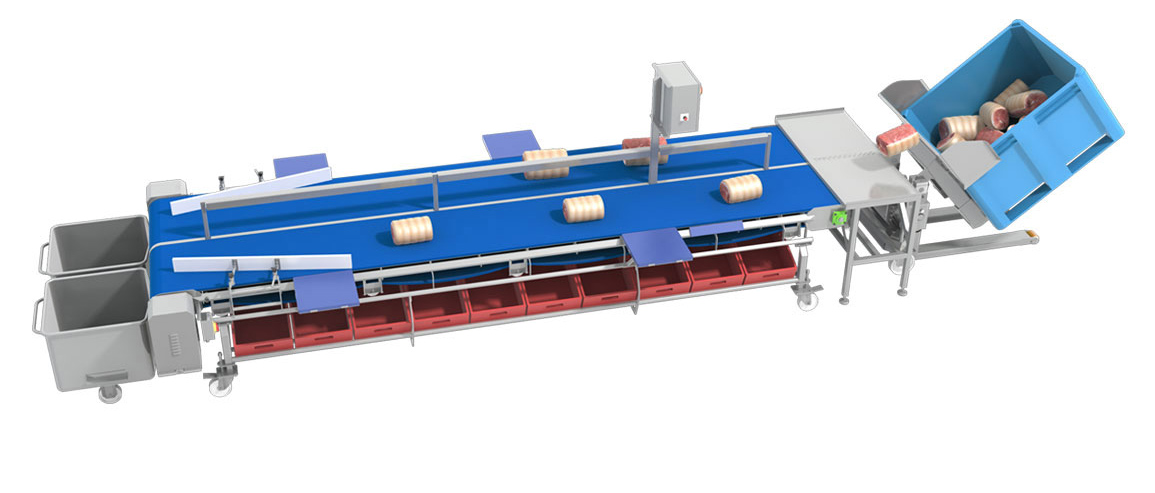

Where Efficiency "Meats" Design

Dolav handling combined with a twin lane belt conveyor for meat processing

applications such as boning and cutting in bulk

Used in this project:

Learn More About This Project:

We were asked by a leading meat processor to develop a way to improve efficiency and throughput of meat processing applications such as boning and cutting. Several important elements to consider were improving productivity whilst maintaining employee safety and meeting the strict hygiene standards required.

Our experienced design team put together a bespoke solution for transporting and unloading the meat product in bulk using our dolav handling equipment. Our robust Dolav Tilter eliminates the need for manual lifting which significantly reduces the risks of staff developing costly musculoskeletal injuries. With its tipping height of 920mm and its tipping angle of 85° depositing the product is a simple and efficient process.

The next element of the project was to develop a conveyor system that could significantly improve throughput whilst still allowing for efficient manual grading of product. The ideal salutation was a Twin lane belt conveyor which allowed twice the product to be processed at once, doubling productivity. However each belt has a variable speed setting to allow operators to set the belt to process product at a speed that is comfortable and safe for them.

Sliding cutting boards with blade protecting covers allow for the operator to easily take product from the conveyor to cut depending on application. The incorporation of tray storage underneath also allows for the easy removal of off cuts or rejects to maintain quality. To ensure the system meets the tough demands of meat processing applications the belts are impact resistant and designed to be accessible for intensive manual cleaning. Adjustable product guides at the end of the conveyor mean that product can be directed into a Eurobin ready to move on to the next stage of the manufacturing process.

This conveyor system compatible with dolav handling equipment and Eurobins was designed to specific dimension provided to us. However thanks to our manufacturing and design capabilities we are able to develop and manufacture solutions to different sizes and specifications depending on application and requirements.

SYSPAL's meat processing line was well received by the customer and fit in well with their existing production processes whilst helping to create a more efficient and lean meat processing line. If you have a similar meat processing requirement, or simply need to improve production efficiency and throughput why not contact us and see what we can do for you?