Feed Systems - Salad

Feed Systems - Salad

Creating the perfect mix

Used in this project:

Learn More About This Project:

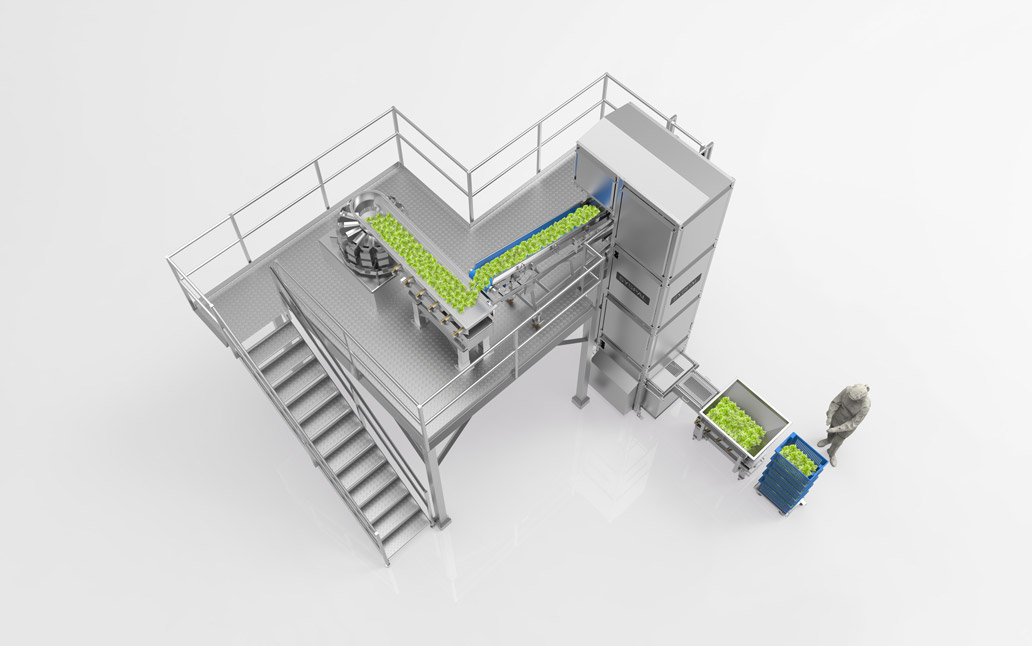

One of our customers recently requested a feed system solution for taking salad leaves up to a gantry to feed a multihead weigher, for bagged salad. The change in level creates manual handling and efficiency issues if employees were to take trays of salad up to the gantry. A well known solution for feeding washed salad up to a gantry to be bagged, would be via an inclined conveyor system. These systems can work well, but have some disadvantages as compared to using a high speed tipper tower. Firstly the incline conveyor would need a larger footprint, taking up valuable production space. Secondly they are harder to clean and keep clean during production. Delicate product such as salad can also have more chance of being damaged or caught up within the belt of the incline conveyors, hence the high speed tipper is a great alternative. Constructed from 304 grade stainless steel, all of the Syspal equipment is designed for ease of cleaning and maintenance. The system meets the strict standards of hygiene for food and pharmaceutical manufacturing environments.

Incorporating a tower lift solution like the high speed bucket tipper, transports medium to high quantities of product within a short amount of time. The bucket tipper is fed via a metering vibratory conveyor loaded with Euro trays of pre washed salad. As long as the operator continues to load the hopper with product, the high speed bucket tipper will lift the product up to the gantry level. A PU belt conveyor transports the tipped product to a spigot discharge vibratory conveyor, which regulates the flow of product into the multihead weigher. The result ensures consistent batches of high quality product that has been transported with great efficiency.

The system minimises downtime and is space saving. This type of solution can be scaled up for larger feed system requirements involving a number of products being fed into the weigh head and multiple weigh heads within the gantry layout. This particular system is ideal for medium scale production needs, that are simply looking for increased efficiency and reduced manual handling. The feed system solution is ideal for a range of applications from pet food, pharmaceutical, salad, chopped vegetable, rice, snacks, cereals, nuts and any other application which may involve a multihead weigh system. Our technical sales team and designers have decades of experience working in a wide variety of product applications. We can help you specify your ideal feed system, meeting the requirements of your product and any space restrictions you may have.

Whether it’s a completely bespoke design or combining standard products with a bespoke component we can create a solution for you. We specialise in making intelligent solutions for processing and packaging no matter what the application or product. If you have the need to make your end of line and packaging more efficient or just want to know if we can design a workflow for your requirements, please contact our technical sales team.

Feed Systems - Salad

Creating the perfect mix

Used in this project:

Learn More About This Project:

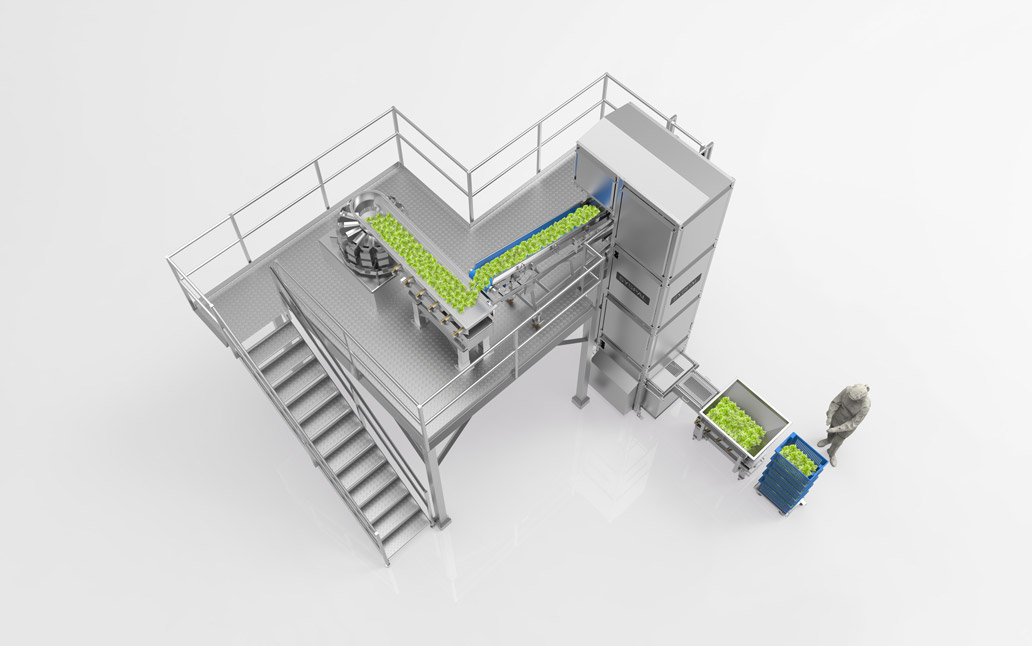

One of our customers recently requested a feed system solution for taking salad leaves up to a gantry to feed a multihead weigher, for bagged salad. The change in level creates manual handling and efficiency issues if employees were to take trays of salad up to the gantry. A well known solution for feeding washed salad up to a gantry to be bagged, would be via an inclined conveyor system. These systems can work well, but have some disadvantages as compared to using a high speed tipper tower. Firstly the incline conveyor would need a larger footprint, taking up valuable production space. Secondly they are harder to clean and keep clean during production. Delicate product such as salad can also have more chance of being damaged or caught up within the belt of the incline conveyors, hence the high speed tipper is a great alternative. Constructed from 304 grade stainless steel, all of the Syspal equipment is designed for ease of cleaning and maintenance. The system meets the strict standards of hygiene for food and pharmaceutical manufacturing environments.

Incorporating a tower lift solution like the high speed bucket tipper, transports medium to high quantities of product within a short amount of time. The bucket tipper is fed via a metering vibratory conveyor loaded with Euro trays of pre washed salad. As long as the operator continues to load the hopper with product, the high speed bucket tipper will lift the product up to the gantry level. A PU belt conveyor transports the tipped product to a spigot discharge vibratory conveyor, which regulates the flow of product into the multihead weigher. The result ensures consistent batches of high quality product that has been transported with great efficiency.

The system minimises downtime and is space saving. This type of solution can be scaled up for larger feed system requirements involving a number of products being fed into the weigh head and multiple weigh heads within the gantry layout. This particular system is ideal for medium scale production needs, that are simply looking for increased efficiency and reduced manual handling. The feed system solution is ideal for a range of applications from pet food, pharmaceutical, salad, chopped vegetable, rice, snacks, cereals, nuts and any other application which may involve a multihead weigh system. Our technical sales team and designers have decades of experience working in a wide variety of product applications. We can help you specify your ideal feed system, meeting the requirements of your product and any space restrictions you may have.

Whether it’s a completely bespoke design or combining standard products with a bespoke component we can create a solution for you. We specialise in making intelligent solutions for processing and packaging no matter what the application or product. If you have the need to make your end of line and packaging more efficient or just want to know if we can design a workflow for your requirements, please contact our technical sales team.