Projects & Processing Solutions

Bespoke Designs for specific applications

We Innovate - Design and Manufacture

Project Case Studies

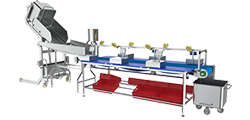

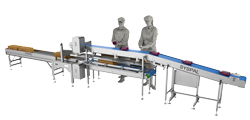

SYSPAL are the UK’s leading specialists in hygienic stainless steel equipment. As experts in bespoke project development, we pride ourselves on our ability to develop innovative project layouts. With over 40 years of experience in design and manufacture, we can create innovative solutions for specific applications to overcome a range of production challenges.

Working on any application from new changing room layouts to creating intelligent packaging workflows, whatever your requirement, SYSPAL can offer a dedicated service for specialist projects. We work closely with you and your team to develop solutions that are unique to your production requirements.

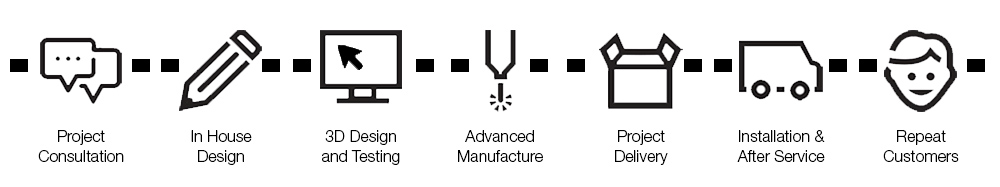

PROJECT CONSULTATION

We work with our customers to design and help manage their projects. A personal approach to working with customers helps us to understand the requirements of each design brief. From one-off pieces of equipment to capital investment projects with multiple assemblies; our technical sales team are involved at all stages of each development.

IN HOUSE DESIGN

With over 40 years of industry experience, our technical sales and design departments work together to satisfy the exacting requirements of our customers. Our design resources are unrivalled within the industries we work in. We thrive on a design challenge!

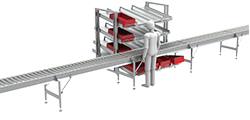

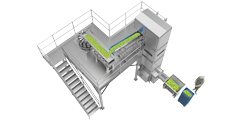

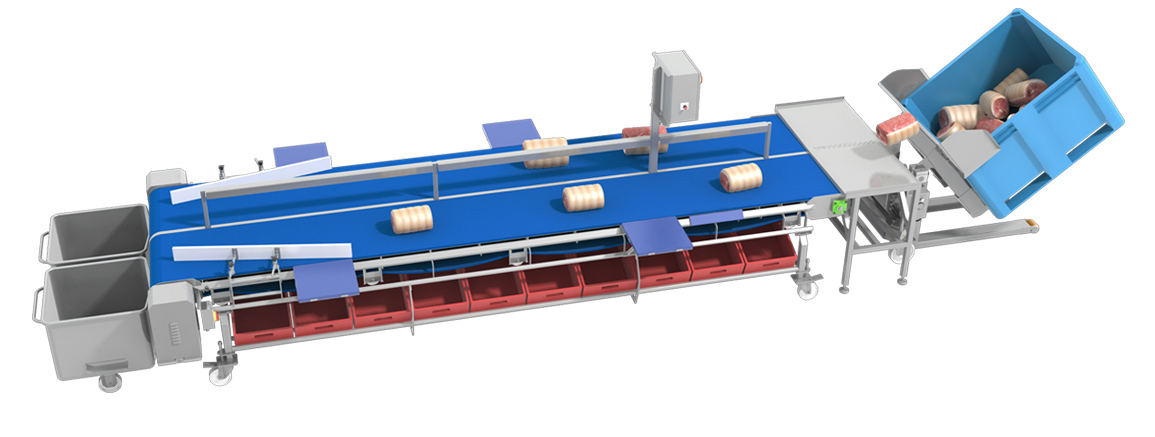

3D DESIGN AND TESTING

Our comprehensive in-house design department use the latest CAD systems to rationalise and justify design concepts. Many of our bespoke projects are realised in full detail and can be pre-tested on screen. Our CAD systems also link directly into our manufacturing processes, this evaluation process prior to manufacture is invaluable.

ADVANCED MANUFACTURE

SYSPAL is the UK's leading manufacturer of stainless steel equipment for hygiene-conscious industries. We invest heavily in the latest technology in manufacturing equipment. We also invest in the skills of our production workforce. h4 class="fs-xs sm-fs-15" design backed up with the finest fabrication keeps our company at the forefront of British manufacture.

PROJECT DELIVERY

Understanding the time constraints of each project we manage the process leading to a stage of delivery. At this point we hope to exceed the expectations of our clients. The planning and management efforts throughout each project come to fruition when we test assemblies in-house and arrange site installations.

INSTALLATION & AFTER SERVICE

Our factory based installation teams take great care during project installation. The skills of these teams are equal to our design and manufacturing divisions. This level of professionalism is often remarked upon by our clients. These same teams use their project knowledge to look after products throughout their life cycle. Prompt after-sales service and maintenance are our specialities.

REPEAT CUSTOMERS

Many of our customers are relationship accounts where we have become the 'go-to manufacturer' for excellence in design and manufacture in stainless steel. We appreciate all our customers and strive to develop our relationships.

Bespoke Designs for specific applications

We Innovate - Design and Manufacture

Project Case Studies

SYSPAL are the UK’s leading specialists in hygienic stainless steel equipment. As experts in bespoke project development, we pride ourselves on our ability to develop innovative project layouts. With over 40 years of experience in design and manufacture, we can create innovative solutions for specific applications to overcome a range of production challenges.

Working on any application from new changing room layouts to creating intelligent packaging workflows, whatever your requirement, SYSPAL can offer a dedicated service for specialist projects. We work closely with you and your team to develop solutions that are unique to your production requirements.

PROJECT CONSULTATION

We work with our customers to design and help manage their projects. A personal approach to working with customers helps us to understand the requirements of each design brief. From one-off pieces of equipment to capital investment projects with multiple assemblies; our technical sales team are involved at all stages of each development.

IN HOUSE DESIGN

With over 40 years of industry experience, our technical sales and design departments work together to satisfy the exacting requirements of our customers. Our design resources are unrivalled within the industries we work in. We thrive on a design challenge!

3D DESIGN AND TESTING

Our comprehensive in-house design department use the latest CAD systems to rationalise and justify design concepts. Many of our bespoke projects are realised in full detail and can be pre-tested on screen. Our CAD systems also link directly into our manufacturing processes, this evaluation process prior to manufacture is invaluable.

ADVANCED MANUFACTURE

SYSPAL is the UK's leading manufacturer of stainless steel equipment for hygiene-conscious industries. We invest heavily in the latest technology in manufacturing equipment. We also invest in the skills of our production workforce. h4 class="fs-xs sm-fs-15" design backed up with the finest fabrication keeps our company at the forefront of British manufacture.

PROJECT DELIVERY

Understanding the time constraints of each project we manage the process leading to a stage of delivery. At this point we hope to exceed the expectations of our clients. The planning and management efforts throughout each project come to fruition when we test assemblies in-house and arrange site installations.

INSTALLATION & AFTER SERVICE

Our factory based installation teams take great care during project installation. The skills of these teams are equal to our design and manufacturing divisions. This level of professionalism is often remarked upon by our clients. These same teams use their project knowledge to look after products throughout their life cycle. Prompt after-sales service and maintenance are our specialities.

REPEAT CUSTOMERS

Many of our customers are relationship accounts where we have become the 'go-to manufacturer' for excellence in design and manufacture in stainless steel. We appreciate all our customers and strive to develop our relationships.